Application of Metroxylon Sago Waste in Textile Process

This journal was supported by National Research Foundation of Korea Grant Funded by the Korean Government(MEST)

이 학술지는 2013년도 정부재원(교육과학기술부)으로 한국연구재단의 지원을 받아 출판되었음

Sustainability is economic, social and environmental systems that make up the community in providing a healthy, productive, meaningful life for all community residents, present and future. The environmental profile of goods and services that satisfy our individual and societal needs was shaped by design activities. The integration of environmental aspect of product design, especially in textiles present much confusion surrounds the incorporation of environmental objectives into the design process. This paper explores the effective use of waste materials that can contribute to the development of more environmentally responsible practice in textile sector. It introduces key elements of the ecological approach and innovative ideas from waste to wealth. The paper focuses on the potential methods of utilizing sago residue as a natural color enhancer in natural dyeing process. It will discover the potential of waste materials to be fully utilized to attempt to make the production of that textile more environmentally friendly.

Keywords:

Sustainability, Textiles, Waste Materials, Environmentally Friendly1. Introduction

The environmental profile of goods and services that satisfy our individual and societal needs is shaped by design activities. Substantial evidence suggests that current patterns of human activity on a global scale are not following a sustainable path. Necessary changes to achieve a more sustainable system will require that environmental issues be more effectively addressed in the design. But at present much confusion surrounds the incorporation of environmental objectives into the design process. Although not yet fully embraced by industry, the product life cycle system is becoming widely recognized as a useful design framework for understanding the links between societal needs, economic systems and their environmental consequences. Life cycle design (LCD), Design for Environment (DFE), and related initiatives based on this product life cycle are emerging as systematic approaches for integrating environmental issues into the design (Keoleian, G,A,, and Menerey, D, 1994).

The Eco design was developed as a concept that focuses on human sustainability priorities together with business inter relations. Its main objective in the improvement of product development methods is to reduce environmental loads. Eco design also gives an inspiration of positive examples of smart products and methods, effective solutions and attractive design. Environmental affection must be integrated into the human lifestyle and throughout the entire life-cycle of all products and services.

2. Design and Environment

A. Review of Textile scenario

The ability of design to influence the environmental profile Tbe ability of design to influence the environmental profile of goods and services was acknowledged by Our Common Future, often referred to as 'The Brundtland Report' (WCED, 1987). Best known for its popularization of the term "sustainable development'’, the report also made recommendations for a new approach to design and production, setting out terms for 'a production system that respects the ecological base' and, 'a technological system that searches continuously for new solutions' (p. 65).

Design has a principal role to play in developing these 'new solutions'. It is estimated that eighty to ninety percent of a product's environmental and economic costs are committed by the final design stage, before production begins (Graedel et at., 1995, p.I7). Therefore, by integrating environmental considerations into the earliest stage of product conceptualization and design development, there is potential to bring far-reaching environmental benefits.

At present environmental considerations fall outside of the area of expertise of most designers. Indeed, in the textile sector, designers have traditionally been seen to be concerned primarily with product styling and to be inexperienced about technical elements of production and associated environmental impacts. Research documented by Heeley (1997), reveals a number of structural and educational reasons why textile designers rarely engage in, and offer solutions to, the environmental debate. The conclusions show that designers are blocked from developing more responsible practice by a role that allows them too little time, knowledge or control over materials and processes; and by design training, whose chief focus is 'task' and not technical or contextual issues such as the environment.

To effect change, a new emphasis on context, 'external', elements of design are needed in which, "every aspect of a product -- its making, its use, its disposal, its meaning, its environmental consequences and its cultural significance - is examined' (Walker, 1997, p.179). This would appear to require a radical transformation of design practice, both in structural terms, where the status of the designer in an organization is re-examined, and in educational terms, where challenges are made to conventional notions of what it means to be a designer. The design process is already carried out under stringent time and cost considerations and, while designers regularly make difficult decisions, the inclusion ofenvironmental objectives in the design process will inevitably make these decisions more complex.

B. Textile approach

In order for design to bring environmental benefits, it appears vital that organizations reexamine their position towards design per se, and that textile designers develop new skills so that they can engage with the challenges and opportunities that environmental impact reduction demands. Minimizing pollution 'end of pipe' and recycling wastes brings limited environmental benefits. Greater benefits can be achieved by adapting existing products and processes, refining them so that they are more resource efficient. The basic concept underlying the ecological approach to design is the life cycle.

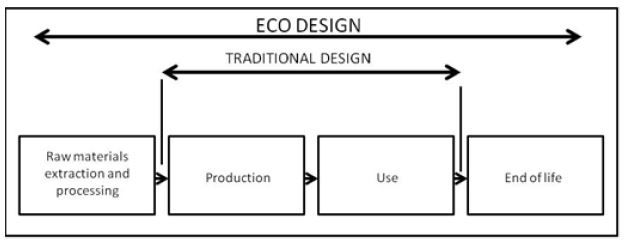

It involves connecting the design of the product to the larger situation of materials extraction, production, use, and disposal, and attempts to minimize environmental impact across this entire life cycle (Fig. 1). Prioritizing impact reduction of the whole system, rather than concentrating on impact reduction of certain process stages, prevents shifting pollutants between air. Land and water or between different life cycle stages (Keoleian and Menerey, 1994, p. 650).

The design of products and of the processes needed to make them have traditionally been two separate and consecutive activities. In contrast, the Lifecycle approach is less linear and relies on design to constantly analyze and re-evaluate the product in the light of environmental constraints on production, use, and disposal. This means that waste, for example, is not simply an 'end of life' environmental problem, but is instead a 'Lifecycle' problem (Van Weenan, 1995, p. 4), and planning to reduce environmental impact at the end of a product's life is as integral to the product development process as reducing emissions in processing.

The value of the life cycle as a design framework suitable for investigating the links between needs, production and environmental impacts, is widely accepted in theory but not fully subscribed to in practice. There are a number of factors, structural and functional, which inhibit the application of a life cycle framework in many industrial settings. One such factor is the focus on process improvement of particular environmental legislation.

Process improvement can be effective in delivering environmental impact reduction, by, example, concentrating on the control of certain process chemicals and waste minimization. In this study, the development of waste to wealth will give a new perspective in textile industry. This newly eco-innovation will enhance quality production in the textile sectors.

3. Utilising Waste is Textile Dyeing

Since textiles world or market highly demand on environmentally friendly textiles, it is appropriate to channel our textiles towards green issues. Eco textiles means the production of textiles concerning the environmental issues related to the use of energy, chemical usage, solid waste, contaminated land, emissions to atmosphere and other environmental issues.

Forming this eco-innovation creates a new dimension in textile industry. The considerations in the eco-innovation focuses on the issues of batik processes cover on the usage of natural wax or starch, natural sources of dyestuffs and mordant. The other criteria are to minimize the disposal of dyes (if using synthetic dyes) in a proper mode. While considering the environmental impact in batik production, R&D in batik production was made by Universiti Malaysia Sarawak looking at a new formulation to replace paraffin wax in the batik designing as well as a dyeing process. In this research, we formulate a natural base method from sago wastes, from sago biomass formula as a solution.

Malaysia is one of the third countries who have largest sago plantation in the world. Around 33.05 million hectares from 2,201 million hectare amount of world sago planting space using in this country after Indonesia and Papua New Guinea who each of this country spends around 1.128 hectares and 953. o33 hectare for sago plantation. Sarawak is one of the states using the largest space for sago plantation in Malaysia. Existences of loose soil, land help sago freely grow in the wild in this area. Sago plantation also works in large scale for commercial purpose since 1986.

Currently sago plantation in Sarawak, Malaysia is approximately 28,000 hectares. With the fast development of this sago plantation, Sarawak will be able to provide around 50, 000 tones of dry sago flour per – year.

4. Methods and Findings

In the Malaysian textile industry, synthetic print pastes are used extensively in the process of designing surface fabrics. Each printing method requires a paste with special characteristics, frequently referred to as flow characteristics. The synthetic thickening agents used are generally extremely high-molecular-weight polymers capable of developing a very high viscosity at a relatively low concentration. However, the thickening are difficult to dispose that create sedimentation to the water during disposal of its wastes. It will be discharged into the drain and rivers that will affect the quality of water and the environment.

In this research, few stages involved in developing new methods for textile prints and dyeing.

A) Sago residue as thickening for printing

B) Sago effluent or waste water as natural color enhancer/fixer.

A. Sago residue formula as thickening

As an alternative to synthetic pastes, natural biodegradable materials developed from sago waste can be used during the printing process. As an alternative to synthetic pastes, natural biodegradable materials developed from 20% of sago starch 80% sago waste/dregs were used during the printing process. We named it as Biopaste since the materials are from natural sources and biodegradable (Figure 2). Since the Biopaste is natural in color, it can blend easily with any natural dye sources or synthetic color. This natural paste can expand up to 50% after mixed with water. The natural Biopaste can create several techniques of printing surfaces on various fabrics such as background layering effect. Furthermore the natural paste is reusable.

Therefore the production cost can be reduced and environmental friendly. It is an advanced formula of the powdery type of paste for printing fabrics compared to existing paste that is in liquid form. It can easily dilute with water to get a starchy type of printing paste. The powdery types of thickening can be re- used many times either in cool or warm mode by just adding warm water. The advantages of using the paste are natural in color, it can blend easily with any natural dye sources or synthetic colors. This natural paste can expand up to 50% after mixed with water. The natural paste can create several techniques of printing surfaces on various fabrics such as background layering effect. Furthermore the natural paste is reusable. Therefore the production cost can be reduced and environmental friendly.

B. Sago effluent as natural color enhancer

In this second research, the alternative method of using sago effluent in natural dyeing process is applied. Basically, in pre-mordant and mordant of natural dyes, a lot of heavy metals additive being used in enhancing natural pigments such as copper, iron, aluminium ammonium sulfate and others. As far as environmental issue is concerned, this product utilizes a combination formula of sago effluent and waste used in dyeing fabrics.

This process involved with developing sago effluent waste and adding it with natural pigment from plants. These combinations are able for the user to mix the formula easily in order to create a dyeing bath . New users of sago effluent as a dyeing mordant as well as a color fixer will optimize the formulation to reduce chemical and water usage (Fig.3).

This research successfully discovers the heterogeneous catalysts as an additive are able to subtract the stinking odor to pleasing smell of sago effluent. The producers of dyes were subjected to examine opportunities to replace toxic and non-biodegradable chemical and dyes with alternatives that have a low toxicity and biodegradable. Results show that this method created natural, subdued and cool color tones to the silk and cotton fabrics. It is a low technology, process, cheap for mass production and environmentally friendly product. This formula will help to improve the production as well as the environment.

5. Conclusions

This paper has explored how environmental impacts could be reduced, and resources conserved, through the effective use of design. The ecological approach to design is grounded in the concept of the life cycle. It involves connecting the design of a product to the larger situation of materials extraction, production, use and disposal, as well as reduce the environmental impact of the whole system. Eco-design is a concept for the production and consumption of goods and services that goes beyond the reduction of negative consequences implied in eco-efficiency and zero emission. Eco-innovation towards eco design positively defines the beneficial environmental, social, and economic traits of goods and services, thereby eliminating the fundamental problems such as material flow quality limitations, antagonism to economic growth and innovation, and toxicity that arise in eco-efficiency strategies especially in textiles.

This continuously accumulating intelligence becomes a perpetual source of added value for products and services, and provides for a supportive relationship between eco-effective industrial systems and long-term economic prosperity. The aim is not only to achieve zero emissions, but to utilize material in a way that maintains or increases their value and productivity over time.

Acknowledgments

This work was done by PRGS grant Malaysia 2013

Notes

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0/), which permits unrestricted educational and non-commercial use, provided the original work is properly cited.

References

-

Keoleian, G. A., & Menerey, D. (1994). Sustainable development by design: review of life cycle design and related approaches. Air & Waste, 44 (5), 647.

[https://doi.org/10.1080/1073161X.1994.10467269]

-

Graedel, T. E., Comrie, P. R., & Sekutowski, J. C. (1995). Green product design. AT&T technical journal, 74 (6), 17-25.

[https://doi.org/10.1002/j.1538-7305.1995.tb00262.x]

- Heeley, J. (1997). Cost Effective Environmental Improvements in the Textile Industry through Design.

- Van Weenan. J. C. (1995). Sustainable Product Development and Waste Management. NY: United Nations Environment.

- Walker, S. (1997). Conscientious Objects. In Eternally Yours: Visions on Product Endurance.

- World Commission on Environment and Development. (1987). Our Common Future. Oxford: Oxford University.